News

- Industry news

Industry news

Rubber and plastic science knowledge - elastomer TPE processing instructions

TPE processing method

1. Injection molding

TPE material injection molding process has the advantages of fast production speed, high efficiency, automatic operation, variety of colors, shape from simple to complex, size from large to small, product size accurate, product easy to update, product shape complex and so on. Injection molding is suitable for mass production, complex shape products and other molding processing fields.

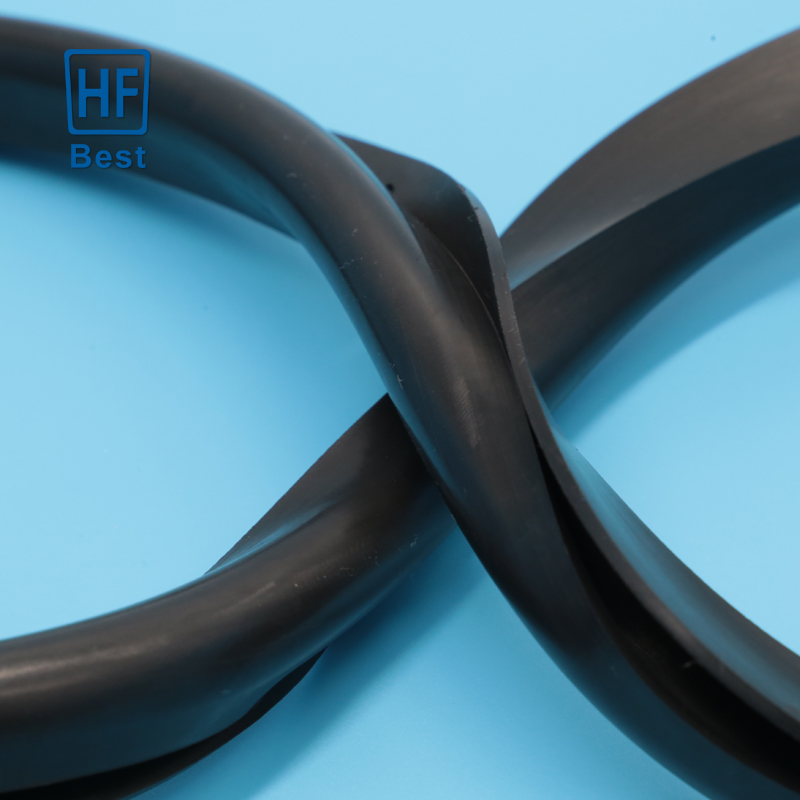

2. Extrusion molding

Extrusion molding mainly produces strip products. Such as wire and cable, water pipes, seals and other products.

3. Blow molding

Blow molding mainly produces toys and auto parts. The main factors affecting blow molding and product quality are blank temperature, mold temperature, cooling time, blow rate, blow pressure and blow ratio.

4. Calender molding

TPE material is calendered by multi-roll calendering machine, mainly for sheet products.

5. Casting molding

SEBS powder is filled with oil to make a viscous TPE material, which is poured into the mold through the sol machine, and is finished after complete cooling. Casting molding mainly produces super soft products and window cut toys.

TPE processing requirements

1, processing temperature

TPE raw materials processing temperature of about 200℃, TPE raw materials in storage will not absorb the moisture in the air, generally no longer need drying process, if the appearance of the product is crucial, raw materials can be blower heating hopper, at 50 degrees temperature drying 2-4 hours.

2, mold degree

Mold degree, higher mold temperature can promote the flow of rubber in the mold, low pressure injection can also fill the mold, the product surface is more beautiful.

3. Injection speed

A higher injection speed is recommended. If the mold has a sufficient exhaust system, even high-speed injection does not have to worry about the phenomenon of trapped gas.

4. Cleaning of the barrel

5. Coloring

Most of the TPE raw materials are transparent, translucent white, it is easy to color, should choose the appropriate color powder or color master coloring.

6, heating and melting

The mixed TPE raw material (usually a paste viscous material) is poured into the melting equipment and heated to melt. The material should be sufficiently melted to ensure the physical properties and appearance of the finished product.

TPE processing precautions

1. Temperature control

The melting point of TPE material is low, generally between 160-180 ° C, thermoplastic materials need to be above the melting point to process molding, therefore, the processing temperature must be controlled within the appropriate range, too high or too low temperature will affect the molding effect.

2. Mold design

TPE material is easy to adhere to the mold, and the processing needs to be relatively high requirements for the design and surface treatment of the mold, and the surface of the mold must be smooth and traceless to prevent stretching and cracking and other defects.

3, mechanical equipment

In TPE processing, hydraulic or pneumatic machinery is more suitable, and the equipment operates smoothly, with high repeatability and stability.

4. Feeding method

The viscosity of TPE material is relatively high, and the feeding method needs to pay attention to uniform, stable and uniform, to avoid the introduction of bubbles and foreign bodies in the feeding process.

5. Processing environment

For the processing of TPE materials, it is necessary to ensure a clean processing environment and avoid the intrusion of impurities and bacteria to ensure the quality and safety of the product.

TPE processing common problems

1. Release variation

Solution: Extend the cooling time; Slow down the mold opening speed; Modify the mold; Reduce mold temperature.

2. Easy to crack and release

Solution: increase cylinder temperature and mold temperature; Modify the mold.

3. The finished product has rays after the mold

Solution: reduce the fire speed, and make the cavity variable air body smoothly discharged; Dry materials; Reduce the molding temperature; Reduce the temperature of the rear section of the feed pipe and increase the pressure.

4. Burrs occur after stripping

Solution: Reduce the pressure, fly mold, increase the locking force; Reduce the injection pressure and maintain the pressure; Reduce burning rate and material temperature; Clean the mold.

5. Insufficient filling of finished products

Solution: Increase the injection pressure, improve the injection speed and clean the mold nozzle; Improve the molding temperature, modify the flow path; Add or increase the vent; Prolong the injection time and increase the injection quantity.

6. The finished product has a binding line

Solution: increase injection pressure, speed, modify gate flow path; Low nozzle temperature; Increase molding temperature and mold temperature, increase back pressure or add screw speed; Adding a blow-off or overflow pool in the confluence section; Reduce the use of release agents.

7. The finished product has poor luster

Solution: improve injection pressure, injection speed, mold temperature; There is water or grease contamination in the mold cavity; Solution, wipe clean; Modify the mold; Increase injection pressure and speed, extend injection time and dry materials.

8. The finished surface has streaks

Solution: Adjust the appropriate injection pressure or rate; Increase the holding time or increase the gate; Increase mold and gate temperature; Increase the temperature, back pressure or speed up the screw speed.

9. Finished product has a rough surface

Solution: increase the temperature, back pressure and screw speed; Increase mold temperature.

10. Lumpy surface of finished product

Solution: re-clean the material pipe; Find the right masterbatch.

11. Expansion of finished products:

Solution: increase mold temperature, reduce screw speed; Adjust the limit device.

Guangzhou?Best?Rubber?And?Plastic?Co.,Ltd.

Tel:(020)31523725, 31523097,15813393170

Tel:(020)31523725, 31523097,15813393170 Fax:(020)37403270, 37403280

Fax:(020)37403270, 37403280 Email: sales@gz-best.com/export@gz-best.com

Email: sales@gz-best.com/export@gz-best.com Add:No. 21 Liangtian Middle Road, Baiyun District, Guangzhou City, Guangdong Province

Add:No. 21 Liangtian Middle Road, Baiyun District, Guangzhou City, Guangdong Province Add:25-27 Yanling Road, Guangzhou

Add:25-27 Yanling Road, Guangzhou

Follow WeChat

COPYRIGHT Guangzhou Best Rubber And Plastic Co.,Ltd. 粵ICP備05087523號